Greenstar is strongly committed to quality and quality control systems are accredited to ISO . The document control system goes through all the production & quality control inspection processes. We have independent quality control department who controls every quality inspection step from incoming material, production process, assembly, packing, as well as cargo shipment. We have established quality evaluation program for each process to assure our customer the best quality products and most professional service.

We have already passed a lot of industry certifications as we deeply know that certificates are crucial. We believe policy is the key to success. We are aware of environmental friendliness as we all want to see a better world. We are very united as we know individual’s power is less powerful than a team’s. By applying high-end equipments and our skilful workers, high quality products can be produced. Customers’ praise is our honor.

Principal of quality assurance: Quality is the heart of business.

Product quality is the key to keep partnership with our customers.

We own a full set of advanced measuring and testing equipment, our team have senior quality control staff who can provide a series of testing reports upon customer’s request at any time such as CPK, FAI PPAP, PFMEA and so on.

Main QC documents:

1.Supplier audit procedures

2.Product identification and products plasticity process

3.Incoming material inspection procedures

4.Inspection procedures for the production process,

5.Final and ex-work inspection procedures

6.Inspection and test status of the control procedures,

7.Nonconforming product control procedure

8.Corrective and preventive measures control procedures

9.Customer complain control procedure

We have set up an integrity quality management system and we will keep improving ourselves to make sure all the parts in hundred percent good condition finally.

Greenstar mold acquires many high precision inspection equipments, to keep the quality of our product .

For each order, Greestar mold would follow with the strick quality guarantee system, from getting order→part analysis→starting design→buying steel→material specification→manufacturing→process control inspection→assembly & mold trial →mold shipping, in order for 100% satisfaction from our customers.

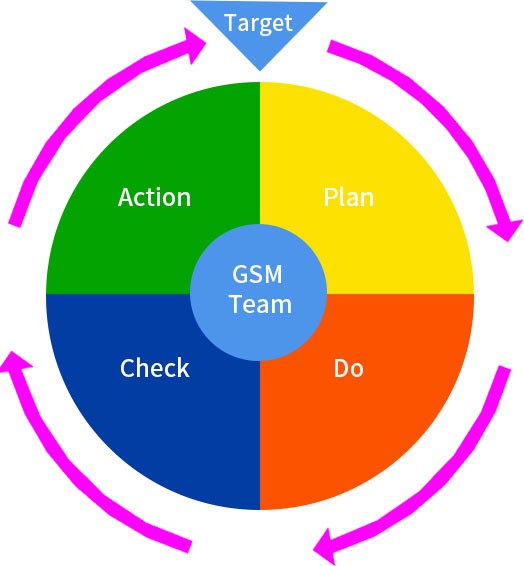

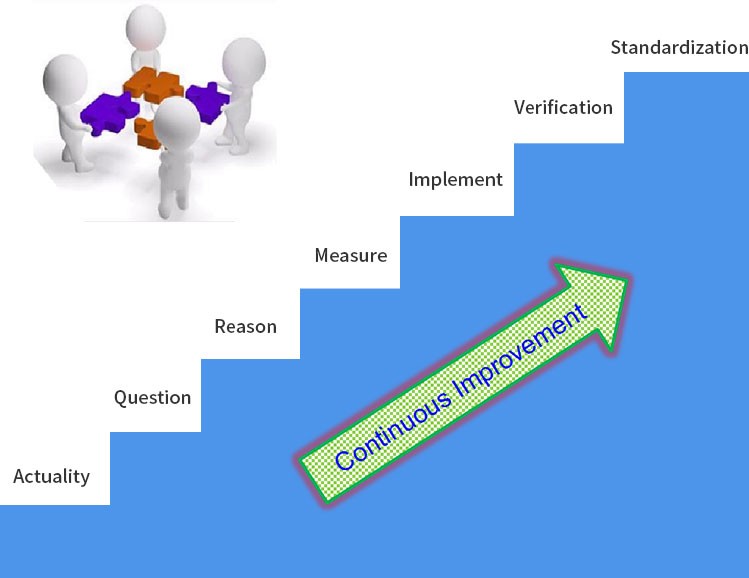

Integrated Quality Management adopted

Everyone likes quality products and services, so every Greenstar mold employee is a trained quality enthusiast. We are committed to provide quality molds and services to our customers and consider the completion of each successful project as fulfillment of our personal goals.

Greenstar mold adopts Integrated Quality Management. Quality is not only implemented by a quality department, but by each department of our company. Our quality management system guides every individual within Greenstar mold to help create high quality products and services

Making occasional mistakes is part of human nature and all kinds of challenges can come our way unexpectedly. With strict quality policies supported by scientific methods, serious attitude and continuous improvement we believe we can meet these challenges.